[Aluminum Road Network] The Aluminum Industry Management Initiative (ASI) recently released a new certification standard for the aluminum industry value chain, which focuses on responsible industrial metal aluminum production, responsible procurement and corporate governance.

ASI's new certification standards will cover all stages of the aluminum value chain, including bauxite mining, alumina refining, aluminum smelting, aluminum fabrication, aluminum product design and manufacturing, and aluminum recycling.

From the date of the announcement, companies that have become ASI members can start certification of ASI standards. ASI's performance standards cover the major aspects of the entire aluminum value chain, including greenhouse gas emissions, waste management, material management, biodiversity, and human rights. The ASI Chain of Custody (COC) standard combines responsible manufacturing with responsible purchasing and will therefore place greater emphasis on sustainability in the procurement process.

AluminiumStewardshipInitiative(ASI)

Aluminum Management Initiative (ASI)

ASI is a non-profit organization dedicated to the development and certification of aluminum value chain standards.

- The ASI vision is to realize the greater contribution of aluminum to the sustainable society.

- ASI's mission is to identify and collaborate to promote responsible aluminum production, responsible purchasing and corporate governance.

The value of ASI includes:

· Make our work and decision making processes more inclusive by promoting and involving all stakeholders.

· Encourage participation from bauxite, alumina to aluminum value chains, and users from mines to downstream aluminum products.

Promote material management in the life cycle of aluminum to ensure joint responsibility for the mining, production, use, and recycling of aluminum.

Introduce

A. Background

The Aluminum Industry Management Initiative (ASI) is a non-profit, multi-stakeholder organization that focuses on the management of independent third-party certification projects in the aluminum value chain. The centerpiece of the ASI certification program is to provide audits of two voluntary standards: ASI Performance Standards and ASI Chain of Custody Standards.

ASI's performance standards define environmental, social, and governance principles and standards to address sustainability issues in the aluminum value chain. Members of ASI who are in the two categories of “Aluminium production and processing conversion†and “Industrial users†must obtain ASI performance standard certification for at least one facility within two years after the ASI certification project is launched or within two years after joining ASI. . For more information, visit aluminum-stewardship.org

ASI's Chain of Custody (CoC) standard (this standard) complements ASI's performance standards. Although ASI encourages members to participate in the implementation and certification of this standard, it is voluntary for ASI members. The CoC standard specifies the requirements for setting up a chain of custody for CoC materials, including ASI aluminum products that are applied to different downstream areas through value chain production and processing.

This standard specifies two starting points for ASI aluminum: primary aluminum (raw) and recycled aluminum (regeneration), which is connected to the aluminum supply chain through a mass balance system, which requires a complete CoC-certified physical chain to supply. It also provides an option for the smelting plant that if the supply chain is long or complex, it is impossible to directly supply physical ASI aluminum to a downstream company through a series of ASI chain-of-custody (CoC) certified entities. They can allocate excess ASI aluminum to virtual ASI credit.

B. Purpose

Over time, the overall goal of ASI is to increase the supply and demand of ASI aluminum through the global value chain, thus providing independent assurance for the responsible production, procurement and corporate governance of aluminum.

The purpose of the CoC standard is to support a responsible supply chain:

• Provide common standards for members of both production and conversion and industrial users who wish to implement a material balance and/or market credit chain of custody system in the aluminum value chain;

• Establish requirements that can be independently reviewed and provide objective evidence for ASI's CoC certification;

• Provide a broader reference for the establishment and improvement of responsible production, procurement and management initiatives in the metal supply chain. .

The implementation of ASI's CoC standard enables the verification of the continuous steps of the supply chain under the ASI performance standard and establishes a relationship with the products passed by the ASI-certified entity.

C. Scope

ASI's CoC standard defines the requirements for entities and facilities to implement a chain of custody management system, including procurement, accounting, and transfer of CoC materials and qualified scrap.

CoC materials are collective nouns, including ASI bauxite, ASI alumina, ASI liquid aluminum, ASI cold material and ASI aluminum, which are manufactured and transported by ASI certified entities in accordance with COC regulatory standards.

At different points of the CoC standard, "CoC material" may be used to refer to any of the above materials, or to a specific one of the above. ASI Aluminium Fluid and ASI Coolant are special forms of ASI Aluminum. Eligible waste is another input, but in general, it does not belong to the CoC material. Unless it is remelted and/or refined, it can be called ASI material, so the qualified waste is classified separately.

Other metals, including metals distributed in alloys, coatings, coatings, composites or product components, and metals such as those found in plastics, glass, coatings, and agricultural products, may be associated with CoC materials at one or more stages of the value chain or Eligible materials are combined, but they are not part of the ASI chain of custody criteria and should be considered neutral.

D. Status and effective date

This standard is the first version of the ASI Chain of Custody standard, approved by the ASI Standards Committee, and adopted by the ASI Board as an ASI standard on December 12, 2017. The first edition takes effect from the date of publication.

E. Development of standards

The development of this standard has undergone a formal and transparent multi-stakeholder consultation process. Initially, this standard was supervised by the ASI Standards Setting Group (SSG) under the coordination of the IUCN. It was then supervised by the ASI Standards Committee and supported by four public comment solicitation periods during 2014 and 2017. It also passed 2017 The test period of the year. ASI is sincerely grateful to the many individuals and organizations that contributed to this standard for their time, expertise, and valuable inputs.

ASI strives to develop standards in accordance with the relevant requirements of the Global Sustainable Standards Alliance ISEAL "Social Environmental Standards Setting Applicable Rules (2014)". More information on the development process of the ASI standard can be viewed at:

Http://aluminium-stewardship.org/standard-setting-process/activities-and-plans/

F. Application

ASI members are committed to responsible production, procurement, and aluminum management, but have different interests, considerations, and priorities for the aluminum chain of custody they purchase and sell. Therefore, although the ASI Chain of Custody (CoC) standard is recommended as a means to increase the ASI performance standard certification value, it is voluntary for ASI members. (The members of the production and conversion categories and industrial user categories in the ASI are required to meet the adaptation requirements of the ASI Performance Standards certification. At least, part of their operation business needs to be certified within two years of the ASI certification project being launched or within two years after they join the ASI. The two time nodes are limited to the later ones.)

However, CoC certification is mandatory for companies when they have stated requirements for any related content such as production or procurement of CoC materials, ASI aluminum, or ASI credit as defined under the ASICoC standard. Without CoC certification, no statement can be made.

The ASI chain of custody standard applies to entities engaged in different supply chain activities, as follows:

The green standard guidelines usually apply to supply chain activities such as within the scope of entity certification.

The orange standard guidelines may apply to supply chain activities - further information can be obtained under standard expressions and CoC standard guidelines.

The use of standards is open to all relevant users. However, CoC certification can only be granted to ASI members or entities controlled by ASI members on the basis of ASI-approved auditor conformance certification.

ASI encourages the certification of ASI Chain of Custody certificates for specific sector-specific plans.

G. Certification

The ASICoC standard is designed for use by ASI-accredited auditors and thus verifies the entity's compliance with ASI chain of custody certification. Note that the certification of ASI performance standards is also a parallel requirement, which is specified in the relevant standards of the CoC standard.

The entity's scope of CoC certification, covering entities defined by the entity's application for certification, including all facilities (including outsourced contractors where applicable), ie all facilities the entity intends to use for processing, accounting, transportation, and/or acceptance of CoC materials. . For ASI credit purchasers, the scope of the CoC certification must include the portion responsible for receiving and calculating the ASI credit, and also includes any part of the related statement or representation.

The steps of ASICoC certification are written in the ASI Assurance Manual, outlined as follows:

• The entity prepares and requires an ASI-accredited auditor to perform the certification audit. This may be separate from or at the same time as the audit of the ASI performance standards.

• During the certification review process, the auditor verifies that the entity has a system that complies with the CoC standard to purchase and/or supply CoC materials. The auditor marks minor non-conformities and directly requires the certified entity to handle such items.

• Once an entity has achieved CoC certification, it will be authorized to issue CoC documents for CoC materials.

• Within 12-18 months, the auditor conducts surveillance audits of entities that have obtained CoC certification to verify that their systems are operating effectively, including issues related to the issuance and receipt of CoC documents. Any minor nonconformities found during the certification audit must be handled prior to the surveillance audit.

• After a valid certification period of 3 years, an additional certification audit is required to update the CoC certification and carry out a surveillance audit within the next 12-18 months.

H. Supporting documents

The following documents provide support information to assist in the implementation of chain of custody CoC standards:

· ASI Chain of Custody CoC Standard Guide

·ASI Declaration Guide

·ASI Guarantee Manual

The ASI performance standards requirements also apply to entities that apply the Chain of Custody CoC standard. Performance standards relate to governance, environmental, and social issues in the aluminum value chain and should be read and implemented in conjunction with the chain of custody CoC standards.

I. Review

ASI promised to review the standard formally before the first year after the first release of the standard, that is, before 2022, or review the standard in advance as required. In particular, ASI promised to review the implementation and effectiveness of the ASI market credit system in its next review, taking into account its expected role as a transitional mechanism. Any proposal for modification or clarification by any relevant group may be submitted at any time, and ASI will consider documenting this during the subsequent review process. ASI will continue to work with stakeholders and members to ensure that these standards are relevant and achievable.

J. Evaluation Impact

The ASI Monitoring and Evaluation (M&E) program is designed to assess the impact of ASI certification. Impact is a long-term change in the field of sustainable development. The standard is designed to focus on these changes. At the same time, these changes are also crucial for understanding and demonstrating standard programs. ASI's monitoring and evaluation plan will seek to measure short- and medium-term changes in order to understand how this change will contribute to long-term impact and determine how the ASI certification program has improved.

In the process of developing and implementing this project, ASI tried to formulate a Code of Good Practice (2014) based on ISEAL's social and environmental impact assessment standards. ASI is subject to its antitrust compliance and confidentiality policies when handling sensitive business information. These policies can be found on the ASI website: https://aluminium-stewardship.org/about-asi/legal-finance-policies/

K. How to read the standard

Please note the following:

• The ASICoC standard is divided into 3 parts and contains 12 chapters.

• Italic texts provide the background and intent of each section, but they are not normative.

• Each chapter's auditable standards are numbered (for example, "1.1").

• All capitalized generic terms and acronyms (such as "Entity Entity") are defined in the glossary at the end of this document.

The three parts of the 12 chapters are structured as follows:

ASI Chain of Custody (CoC) Standard

A. CoC Integrated Management (Chapter 1-2)

1. Management system and responsibilities

Chapter 1 outlines the elements that an entity needs to effectively implement the management system that an ASICoC standard should have. The entity may consist of a single facility or multiple facilities, but it must be controlled by ASI members to link ASI's membership obligations with the ASI complaint mechanism. The standards in this chapter can often be incorporated into existing management systems related to sales, purchasing, and inventory management.

1.1 The entity applying for CoC certification shall be an ASI member with good performance in both production and conversion or industrial user categories, or under the control of an ASI member, in order to comply with the ASI membership obligations and the ASI complaint mechanism.

1.2 The entity should have a management system that addresses all applicable requirements of the CoC standard and covers all facilities under the control of the entity under the supervision of CoC Materials.

1.3 Entities should ensure that the management system of Standard 1.2 is regularly reviewed and updated based on implementation experience and deal with areas that may not be met.

1.4 The entity should designate at least one representative of the manager who has full authority and authority over the entity's compliance with all applicable requirements of the CoC standard.

1.5 The entity shall establish and implement communication and training measures so that relevant personnel can understand and fulfill their own responsibilities under the CoC standard.

1.6 The entity shall maintain new records covering all applicable requirements of the CoC standard and retain at least the relevant records for (5) years.

1.7 If necessary, the entity should report the following information to the ASI Secretariat within 3 months after the end of each calendar year:

a. All Entities: Inputs and CoC Materials/Outputs over the years.

b. All Entities: Input percentage calculated over the years.

c. All Entities: Large positive balances (if any) that have been carried forward to the subsequent material accounting period over the years.

d. All Entities: The overdrafts within the calendar year and the percentage of CoC material represented as such, if any.

e. The entity is engaged in aluminum remelting/refining. Production of recycled aluminum: The total input of waste that meets the conditions over the years and is classified according to post-consumer waste and waste before consumption. The classification basis is based on the CoC material directly supplied by the CoC certified entity.

f. Entity engaged in the production of fused products: ASI aluminum quantity assigned to ASI credit over the years.

g. Subsequent entities in the smelting shop using ASI Credit: ASI credits purchased over the years.

Outsourcing contractor

Encourage outsourcers to make CoC certification on their own terms. However, it is generally accepted that CoC-certified procurement is challenging in longer or flexible supply chains or in smaller businesses. Chapter 2 provides CoC-certified entities the ability to outsource processing and processing or manufacturing of CoC materials, which they own or control as part of a non-CoC-certified outsourcer, and covers them based on their own CoC certification.

2.1 Any outsourced contractor not certified by CoC shall take over the entity's COC material for further processing, processing or manufacturing purposes, and shall be determined within the scope of the entity's COC certification.

2.2 The entity that wishes to include an outsourced contractor in the scope of CoC certification should ensure the following:

a. The entity must have legal title or control over the use of CoC materials by these outsourced contractors.

b. Any outsourced contractor included in the scope of an entity certification shall not outsource any processing, processing or manufacturing of CoC materials to any other contractor.

c. The entity assesses potential inconsistency risks based on the CoC criteria. These risks are derived from the participation of each outsourcer, and based on the risk assessment, consider the risk to be acceptable.

2.3 The entity should ensure that the outsourcer provides information on the output of the CoC material and ensures that the outsourcer delivers it to the entity at the end of the physical material review period (or more requested by the entity).

2.4 The entity shall have a system in place to verify that the output of the CoC material of the entity is consistent with the input of the CoC material provided to the outsourcer and recorded in the material accounting system.

2.5 After the shipment of CoC materials, if found to be in error, the entity and outsourcing contractor will need to make a mark, agree to take steps to correct it, and take action to avoid false recurrence.

B. Confirmation of Passing Input (Chapter 3-7)

3. Primary Aluminium: Standards for ASI Bauxite, ASI Alumina and ASI Alumina

The chain of custody must have a starting point. For aluminum, it is a primary aluminum (mineral) or recycled aluminum (recycled) material. Chapter 3 focuses on primary aluminum and requires that ASI bauxite come from bauxite mines and be further processed through alumina refineries and aluminum smelters, which also need to comply with ASI performance standards (or equivalent).

3.1 The entity engaged in bauxite mining should have a corresponding system to ensure that the ASI bauxite is only produced from bauxite mines:

a. CoC certification scope of the entity, and/or the legitimate equity capacity held by the entity, but belonging to CoC certification scope of another CoC certification entity;

b. Accredited in accordance with the ASI Performance Standards, or certified by the ASI for Responsible Mining Standards that are equivalent to the ASI Performance Standards.

3.2 The entity engaged in alumina refining shall have a corresponding system to ensure that ASI alumina is produced only by alumina refiners:

a. The scope of the CoC certification of the entity, and/or the legal equity capacity held by the entity, but within the CoC certification scope of another CoC certified entity;

b. ASI performance standards for certification.

3.3 The entity engaged in aluminum smelting shall have a corresponding system to ensure that ASI aluminum liquid is produced only by the aluminum smelter:

a. The scope of the CoC certification of the entity, and/or the legal equity capacity held by the entity, but within the CoC certification scope of another CoC certified entity;

b. ASI performance standards for certification.

4. Recycled aluminum: standard for qualified scrap and ASI aluminum fluid

Recycled aluminum is the second potential starting point for the ASI aluminum chain of custody. The CoC standard expects that the first entity in the chain of custody of recycled CoC materials will be an aluminum remelting and/or refinery (aluminum refining includes the recovery and refining of aluminum from scum and scum residue as slag). Chapter 4 requires that the “know your customer†principle applies to recycle scrap suppliers (also suitable for Chapter 7 due diligence requirements). This section describes the ASICoC standard requirements for entities that produce recycled waste and recycled aluminum.

4.1 Entities engaged in the remelting/refining of aluminum to produce recycled aluminum should have a corresponding system to ensure that ASI aluminum fluid can only be produced from existing equipment:

a. CoC certification scope of the entity, and/or the legitimate equity capacity held by the entity, but belonging to CoC certification scope of another CoC certification entity;

b. ASI performance standards for certification.

4.2 The entity engaged in aluminum remelting/refining, in its material accounting system, only lists the following waste as eligible waste:

a. Pre-consumer waste, designated as CoC material, which is supplied directly from CoC certified entities or aluminum recovered from dross and scum waste, subject to supplier due diligence mentioned in Chapter 7 ;and / or

b. Post-consumer waste, post-consumer waste that is subject to the supplier's due diligence in Chapter 7, is derived from post-consumer waste that is assessed by the entity.

4.3 The entity engaged in aluminum remelting/refining to produce recycled aluminum should have a recording system:

a. The identity, person in charge, and place of business of the direct supplier of all recovered waste.

b. The financial records of all transactions with the direct supplier of all recovered wastes, if the transaction is a single operation or performed in several linked operations, it shall be ensured that the cash payment amount is below the applicable legal limit or US$10,000 ( Or equivalent).

5. Casting: ASI Aluminum Standard

For primary and recycled aluminum, the smelting shop is the “bottleneck†between the upstream and downstream supply chains, and the key to aluminum forming a usable (or reusable) metal in subsequent material conversion and/or manufacturing processes. point. Chapter 5 discusses the certification requirements for the casting shop, as well as the input and output of molten aluminum and cold materials, which are also part of the casting process. It also stipulates that the smelting plants need to ensure that their systems can provide traceability of ASI aluminum products and ASI credits through labeling and marking.

5.1 When an entity uses primary aluminum and/or recycled aluminum to produce fused cast products, it should have a corresponding system to ensure that ASI aluminum only originates from the following smelting plants:

a. In the scope of the entity's CoC certification, and/or the entity holds a legitimate equity capacity, which is a CoC certification scope of another CoC certified entity;

b. ASI performance standards for certification.

5.2 For purposes of traceability, when an entity is engaged in the production of fused and cast products, the accounting system shall have a corresponding system to ensure that the ASI product has a unique identification code, which may be labeling and/or printing on ASI aluminum, or following ASI. Aluminum, and associated with the input of CoC material during the accounting of this material.

6. Casting Follow-up: ASI Aluminum Standard

Casting products are widely used in semi-finished products processing and subsequent material conversion, downstream product manufacturing and product use. Supply chains starting from post-casthouses are often highly diversified and/or dispersed. Chapter 6 applies to entities that produce smelting follow-up products. They purchase physical ASI aluminum directly from the production entity of the fused product or through another downstream entity, and use the CoC standard to make a statement for ASI Aluminum, which it produces.

6.1 Production entities for smelting subsequent products Procurement ASI aluminum shall have a corresponding system to ensure that its own production of ASI aluminum only originates from the following entities and/or facilities/:

a. Within the entity's scope of CoC certification, and/or the entity holds a legitimate equity capacity, but is within the scope of CoC certification of another CoC certified entity;

b. ASI performance standard certification should be obtained. This process needs to be completed within two years after the ASI certification program is started or

c. Purchase ASI Aluminum from another ASICoC-certified entity, or through a metal trader or warehouse. Among them, ASICoC authentication entities can provide or verify related CoC files, which contain supplementary information, sufficient to determine the corresponding shipping process.

7. Due Diligence for Non-CoC Input and Recycling Waste

Chapter 7 requires entities to conduct due diligence on suppliers of non-CoC materials and recycled scrap, covering environmental, social or governance risks, and reasonable measures taken to prevent or mitigate risks. This is consistent with ASI's mission of promoting responsible purchasing. This does not preclude entities from purchasing from non-ASI vendors.

7.1 Entities should implement a responsible procurement policy and communicate with the covered aluminum, non-CoC materials, and recycling scrap suppliers. At a minimum, the following ASI performance standards guidelines must be considered:

A.1.2 (Anti-corruption)

B.2.4 (Responsible purchasing)

C.9.1 (human rights due diligence)

D.9.9 (in conflict-affected and high-risk areas)

7.2 The entity shall base its non-CoC materials and waste recovery suppliers on non-compliance risk assessment based on the responsible procurement policy, record the investigation results, and perform appropriate risk mitigation on the identified adverse effects.

7.3 The entity should establish a complaints mechanism in accordance with Criterion 3.2 of the ASI Performance Standards, which is compatible with the nature, scale and impact of the company, and allows relevant parties to express concerns about non-compliance with the procurement policy of their aluminum supply chain.

C. CoC Accounting, Documentation, and Declarations (Chapter 8-12)

8. Mass Balance System: CoC Material and ASI Aluminum

The mass balance system requires each successive entity handling the CoC material to do CoC certification and create a complete chain of custody. It allows the mixing of CoC materials with non-CoC materials at any time in the value chain and at any stage of the value chain. A physical material accounting system for recording and calculating input percentages and outputs of CoC materials. Please note that the CoC standard states that the output of CoC material cannot be assigned as "partial CoC" - if the output is 20% is "CoC" then the 20% output is 100% CoC (not all outputs Is "20% CoC").

8.1 The entity's management system should include a material accounting system that records input and output of CoC materials and non-CoC materials by material quantity.

8.2 Entities engaged in the remelting/refining of aluminium for the production of recycled aluminium shall also record the following breakdown of the recovered waste in their material accounting system:

a. Input amount of post-consumer waste.

b. Pre-consumer waste input (total).

c. The amount of qualified waste in the pre-consumer waste input, which is supplied directly by CoC-certified entities (if applicable).

8.3 The entity's material accounting system shall specify a material accounting period not exceeding 12 months.

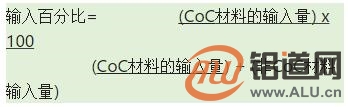

8.4 For a given material accounting period, the entity shall use the following formula to calculate and record the input percentage (other than 8.5 applies):

Input percentage = (input amount of CoC material) x100

(Input amount of CoC material) + (non-CoC material input amount)

The units in the numerator and denominator must be the same.

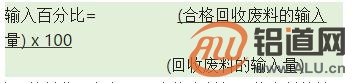

8.5 For a given material accounting period, an entity engaged in aluminum remelting/refining shall use the following formula to calculate and record the input percentage:

Input percentage = (qualified recycle waste input) x 100

(input amount of recycling waste)

The units of numerator and denominator must be the same. The input of qualified and recycled waste should be based on an assessment of aluminum content.

8.6 For a given material accounting period, entities should use input percentages to determine the output of CoC materials by quality.

The output of 8.7CoC materials may only be part of the total production, and should also be classified as 100% CoC material.

8.8 If the entity generates pre-consumer waste from the process and wishes to use the appropriate proportion as qualified waste, the entity should use the input percentage to determine the production of qualified waste during the given material accounting period.

8.9 The entity's material accounting system shall ensure that the total output of CoC materials and/or qualified scrap during the material accounting period cannot exceed the percentage of the total input of CoC materials and/or qualified scrap.

8.10 For a given material accounting period, CoC materials are delivered to an entity under contract, subject to force majeure. At this time, the entity's material accounting system can carry over internal overdrafts to subsequent material accounting periods.

a. Internal overdrafts must not exceed 20% of the total input of CoC materials during the accounting period.

b. The internal overdraft shall not exceed the amount of Force Majeure material affected by force majeure.

c. Internal overdrafts should be covered in the subsequent material accounting period.

8.11 At the end of the accounting period for a material, when a physical unit has a positive balance of output CoC material, it can be extended to the subsequent material accounting period.

a. The entity's material accounting system must clearly identify any continuation of the positive balance.

b. Positive balances incurred during a material accounting period and carried over to subsequent material accounting periods and, if not, are due at the end of the accounting period.

9. Issuing CoC files

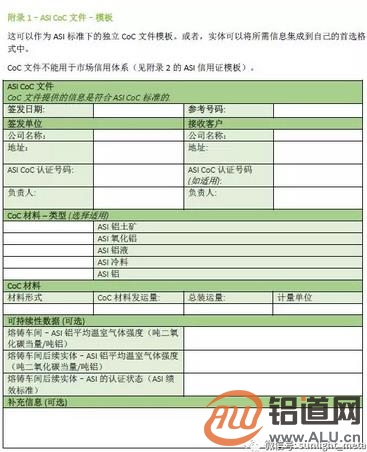

The mass balance system is supported by precise CoC information accompanying the flow of CoC material. In the CoC standard, the set of required CoC information is called a CoC file (see template in Annex 1). Entities usually integrate CoC information into their usual shipping processes, such as sales invoices or shipping documents. Additional data and information may also be left to the company to decide whether it is included in the CoC file, but it must be accurate and verifiable.

9.1 The entity shall ensure that CoC documents are accompanied by each CoC material shipped or transferred to a CoC-certified entity or outsourced contractor.

9.2 The entity shall ensure that the CoC file includes at least the following information:

a.CoC document issuance date.

b. CoC file reference number, which is associated with the entity's material accounting system for verification.

c. The identity, address, and CoC certificate number of the company that issued the CoCo certificate.

d. The customer's identity and address of the received CoC material, if it is another CoC certified entity, they will also need their CoC certification number.

e. Responsible person from the entity company who can verify the CoC file information.

f. A confirmation statement stating that "the information provided in the CoC document complies with ASICoC standards."

g. Type of CoC material shipped.

h. CoC material shipments.

i. Total shipment of goods.

9.3 When a related entity undertakes one or more of the following activities, it also needs to include the applicable sustainability data in the CoC document corresponding to the CoC material:

a. Entities engaged in aluminium smelting and/or aluminium remelting, refining and/or smelting operations: the average intensity of greenhouse gas emissions (range 1 and range 2), ie the carbon dioxide equivalent value produced per ton of ASI aluminium produced from ASI aluminium CO2–eq, including emissions from the smelting process during the material accounting period.

b. Casting Subsequent Entities: The average intensity of greenhouse gas emissions (ranges 1 and 2), where available, ie the carbon dioxide equivalent value of CO2–eq per ton of ASI aluminum, which it receives in the CoC file 9.3a The information provided is based on.

c. Casting Subsequent Entities: The ASI certification status of the ASI Performance Standards is for entities and/or facilities that issue CoC files.

9.4 If the CoC document includes supplementary information on the entity or CoC material, it should ensure that the supplemental information can be supported by objective evidence.

9.5 The entity shall have an appropriate system in order to respond to the information verification request in the CoC file issued by the entity.

9.6 If errors are discovered after the CoC material is shipped, the entity and the recipient should record the error and agree to take steps to correct it and take action to avoid recurrence.

10. Receive CoC files

Entities receiving CoC materials will also receive CoC documents (Chapter 9) issued by the supplier. The entity will check and record this information to support the accuracy and reliability of the quality balance system.

10.1 The entity shall verify that all information required in accordance with guidelines 9.2 and 9.3 is included in the received CoC file.

10.2 The entity shall verify that the received CoC file is consistent with the accompanying CoC material or qualified scrap, a process that needs to be completed prior to recording in the material accounting system.

10.3 The entity should regularly check the ASI website to verify that the supplier's ASICoC certification has changed, and these changes will affect the status of the supplied CoC materials or qualified scrap.

10.4 If an error is found after the CoC material is shipped, the entity and the recipient should record the error and agree to take steps to correct it and take action to avoid recurrence.

11. Market Credit System: ASI Credit

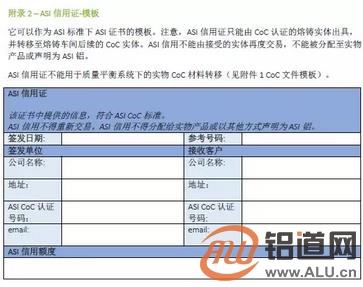

Some entities engaged in the business of smelting subsequent products may find that establishing a complete CoC certification chain including their direct suppliers is challenging, at least at the initial stage, thus limiting the quality of their use. Balance the system. When ASI Aluminum, produced from a CoC-certified fused casting entity, cannot directly transfer to another CoC-certified entity or facility as a CoC-certified material, the market credit system allows such ASI aluminum to be assigned to a CoC in the form of ASI credit. A certified entity engaged in the smelting of subsequent businesses. ASI credits are separated from physical materials and therefore cannot be returned to the product or restated as "ASI Aluminum." Appendix 2 contains the ASI letter of credit template.

11.1 Entities engaged in the fused castings business may allocate excess ASI aluminum to ASI credits and have appropriate systems to ensure:

a. The amount of ASI Al allocated to the ASI Credit is included in the entity's material accounting system.

b. The physical material accounting system has a unique identification number that can be associated with ASI Aluminum's fused cast products for ASI credit allocation.

c. ASI credits allocated by ASI Aluminum cannot be double counted.

d. Allocate and issue ASI credits during a material accounting period. The positive balance of the ASI credit cannot be transferred to the subsequent material accounting period.

11.2 Credit transactions shall be recorded in the ASI Credit and electronically shared between the supplying and purchasing entities. The entity that issues the ASI letter of credit should include the following information:

a. ASI letter of credit issuance date.

b. A reference number for the ASI Credit, which is linked to the entity's material accounting system for verification purposes.

c. The identity, address, contact email address, and CoC certification number of the entity that issued the ASI credit.

d. The identity, address, contact email address, and CoC certification number of the entity that received the ASI credit.

e. The statement confirms that "the information provided by the ASI Credit complies with ASICoC standards."

f.Statement: "ASI credits may not be traded anymore, and may not be returned to the product or restated as ASI aluminum."

g.ASI credit limit.

11.3 The smelting follow-up entity that purchases ASI credit should have a corresponding system to ensure:

a. The ASI credit purchased by the entity or facility is within the scope of the CoC certification of the procuring entity.

b. The material accounting system of the procuring entity accurately accounts for the ASI credit of the procuring entity and keeps a verifiable record of all ASI credits.

c. ASI credits purchased during the material accounting period expire at the end of the period. The positive balance of the purchased ASI credit cannot be transferred to the subsequent material accounting period.

d. The letter of credit cannot be traded again.

e. L/C cannot be assigned to a physical product, nor can it be called ASI Aluminum.

f. At ASI's official website, periodically verify the ASICoC's effectiveness and scope of the supplier so as not to affect its creditworthiness.

g. The ASI Credit purchased by the entity is valid for up to 5 years from the initial purchase.

12. Statement and Communication

Encourage CoC-certified entities to communicate with their users and consumers about responsible supply chain transactions. All marketing and communication requirements, beyond the scope of CoC documents or ASI letters of credit, must ensure compliance with ASI-related standards and are consistent with the ASI Statement of Guidance.

12.1 Entity's Statements or Statements on CoC Materials The scope of the CoC documents, or statements or statements regarding ASI credits, are beyond the scope of the ASI Credit, the entity should have an appropriate system to ensure:

a. These are made in a manner and in a form that conforms to the ASI Statement of Claims.

b. There is verifiable evidence supporting the statement and/or statement made.

Provide relevant staff with appropriate training to correctly understand and communicate statements and/or statements.

This standard supports documents: ASI Chain of Custody CoC Standard - Guide

The ASICoC standard outlines CoC certification requirements. The developed CoC standard guide is used as a resource to assist ASI members in applying for CoC certification, and ASI certified auditors perform independent third-party audits. This guide is also for anyone who wants to learn more about establishing a chain of custody system and ASI standards.

The ASICoC standard guide provides comprehensive guidance to companies that implement a systematic and procedural approach to the CoC standard.

Like the ASI performance standards, the CoC standard specifies what companies must do, but does not specify how the system and program design can be implemented to achieve these aspects.å› æ¤ï¼ŒCoCæ ‡å‡†æŒ‡å—æ供了背景,解释和考虑的è¦ç‚¹.

背景信æ¯ï¼š

ç›®å‰ï¼ŒASIçš„60多个æˆå‘˜ï¼ŒåŒ…括有代表性的民间社会组织ã€é“土矿开采ã€æ°§åŒ–é“精炼ã€é“冶炼ã€åŠæˆå“åŠ å·¥ä¼ä¸šã€äº§å“å’Œé›¶éƒ¨ä»¶åˆ¶é€ å•†ã€æ¶ˆè´¹å“和商业产å“生产商(包括汽车工业,建ç‘和包装),以åŠç›¸å…³è¡Œä¸šå会和其他支æŒè€…。

ASI继ç»å¯»æ±‚与全çƒé“价值链ä¸çš„商业实体和利益相关方进行åˆä½œã€‚有兴趣æˆä¸ºä¼šå‘˜çš„å…¬å¸ç»„织å¯ä»¥æ›´å¤šäº†è§£ASI的会员结构以åŠç”³è¯·åŠ 入的方法。

ASIç›®å‰éƒ¨åˆ†ä¼šå‘˜ä¼ä¸šï¼š

力拓ã€æµ·å¾·é²é“业ã€é˜¿è”é…‹å…¨çƒé“业ã€ç¾Žé“ã€è‚¯è”é“业ã€ä¿„é“ã€è¯ºè´ä¸½æ–¯ã€çˆ±åŠ±é“业ã€å¥¥ç§‘å®å…‹ã€æ¬§æ´²é“ç®”ã€å¥¥åœ°åˆ©é“金属ã€æ±Ÿè‹ä¸åŸºã€å®‰å§†ç§‘ã€å·´è¥¿CBAã€AludiumPremiumAluminium,波尔公å¸,,康斯å¦èŽŽè½¯åŒ…装,JupiterAluminumã€ç¥žç«é“ç®”ã€é‡‘æ¡¥é“æã€å¥¥è¿ªã€å®é©¬ã€æ·è±¹è·¯è™Žã€é›€å·¢ã€æ—æ ¼å›½é™…ã€åˆ©ä¹ã€è‹¹æžœã€FromageriesBel食å“集团ã€EnergiaPotiorLtd,ã€RONAL轮毂集团ã€Regain,Materialsã€Lavitã€GulkulaMiningã€BridgnorthAluminiumã€æ™Ÿé€šç§‘技集团......

ï¼ˆå±žäºŽç”Ÿäº§å’Œè½¬åŒ–åŠ å·¥ç±»åˆ«çš„ä¼šå‘˜å°†åœ¨2年内å¯åŠ¨ASIç»©æ•ˆæ ‡å‡†å’ŒASIç›‘ç®¡é“¾æ ‡å‡†çš„è®¤è¯ï¼‰

ASI相关支æŒæ–‡ä»¶å’Œå‚考资料:

下列文件æ供了é¢å¤–的支æŒä¿¡æ¯ï¼Œä»¥å助实施ASIæ ‡å‡†ï¼Œå®žæ–½å’Œäº¤æµASI认è¯ï¼š

·ASI会员信æ¯å’Œç”³è¯·è¡¨

·ASIç»©æ•ˆæ ‡å‡†

·ASIç›‘ç®¡é“¾æ ‡å‡†

·ASIç»©æ•ˆæ ‡å‡†æŒ‡å—

·ASIç›‘ç®¡é“¾æ ‡å‡†æŒ‡å—

·ASI声明指å—

·ASIå®¡æ ¸å‘˜è®¤å¯ç¨‹åº

·ASIå®¡æ ¸ç›‘ç£æœºåˆ¶ï¼ˆå°†äºŽ2018å‘布)

·ASI监测和评价计划(将于2018å‘布)

·ASI注册专家程åº

Abrasive Flap Disc

Abrasive flap discs, commonly known as flat emery cloth wheels, flap discs, flower impellers or elastic discs, are a large variety of coated abrasive conversion products. It is a method of pressing the cut coated abrasive discs one by one. It is formed by sticking adhesive to the back cover plate along the circumference.

The Flap Disc is mainly installed on hand-held Power Tools for grinding and polishing the welds, burrs, chamfers, surface derusting, surface polishing, etc. of various metal and non-metal parts. Compared with the resin grinding wheel for fixed abrasives, it has Grinding and polishing can be completed at one time, shortening the operation time, saving the cost of grinding, and improving the grinding efficiency. The abrasive self-sharpness is strong and the utilization rate is high. The air cooling does not damage the surface. The surface quality is easy to control and cost-effective, reducing operator fatigue and increasing machine life. And so on, so it is widely used in various industries or fields of manufacturing.

The related abrasive products we can supply is Flap Disc Adhesive, Flap Wheels , bonded abrasives, and Abrasive Sanding Disc, such as Abrasive Fiber Disc, Sanding Screen Disc, abrasive silicon sandpaper, if you have any needs about abrasive tools, please kindly feel free to contact us.

Abrasive flap disc can be divided into flap disc, Mini Flap Disc and Flexible Flap Disc according to their shape. There are subtle differences in usage. The flap disc are relatively hard and not easy to bend; the blades of flexible flap disc can be bent at will. Shape, suitable for grinding the edges and corners of the workpiece; mini flap disc is suitable for grinding smaller workpieces. The following is a detailed introduction of the flap disc.

According to the different abrasives, it can be divided into Zirconia Flap Disc,S/C Flap Disc, Ceramic Flap Disc.

1.Zirconia Flap Disc

Mainly used for high alloy, stainless steel and heat-treated steel; high-tensile, non ferrous metals.

2.S/C Flap Disc

Mainly used for marble, stone, glass, and non-ferrous metals.

3.Ceramic Flap Disc

Mainly used for grinding stainless steel, titanium, inconel, and other hard metals.

At present, flap discs are widely used in automobiles, stainless steel products, metal products, glass manufacturing and other industries, and have special effects on welds, solder joints, flash, rust removal and surface polishing. The reason why the flap disc is so widely used is because it has five advantages that cannot be ignored:

1. The flap disc blades have high hardness, high strength and strong grinding ability during use.

2. The flap disc has low noise, low vibration and long service life during use.

3. The flap disc has strong wear resistance and long service life.

4. It is not easy to generate heat and burn parts during use.

5. The use of flap disc can improve work efficiency.

The flap disc blades can be used instead of resin Grinding Wheels and steel wire wheels. They have a good effect on rust removal, grinding and polishing. It is a good way to polish and remove rust. It is worth choosing!

Abrasive Flap Disc,Abrasive Disc,Toolstation Flap Disc,Silicon Carbide Flap Disc

Zhengzhou Jiading Abrasive Manufacturing Co.,Ltd , https://www.jd-abrasives.com